actuate and automate your machine document the group project and your individual contribution

Machine Design

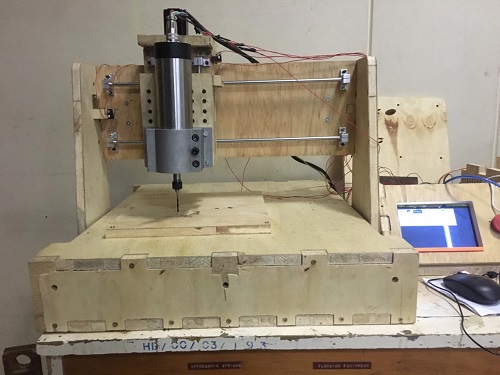

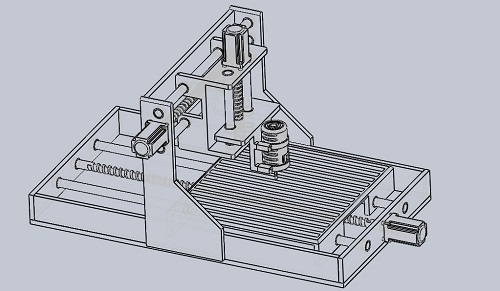

CNC machine design

Brainstorming

The first task was to sit down and decide what kind of machine we would like to produce and the major question being what would be the fuction of this machine at the end of the day.

this brought up a list of prodcts that could be produced using different machines in any setting and this gave us an opprtunity to vist one of well know areas for producing artifacts like earings braceletts on which are both cut from different material products

this also brought the quation of making the ease of work while using the machine that we would produce

After several discussion we decided to settle for a cnc routing machine

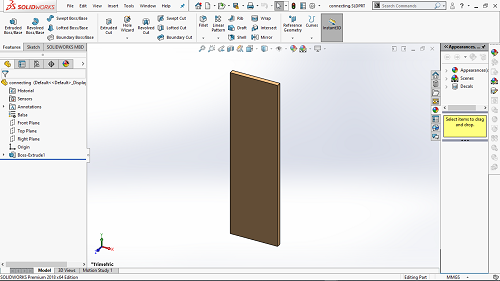

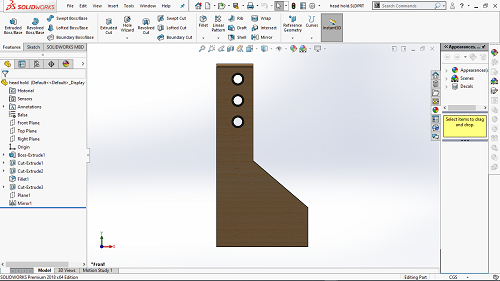

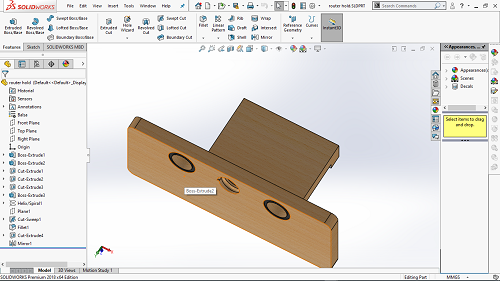

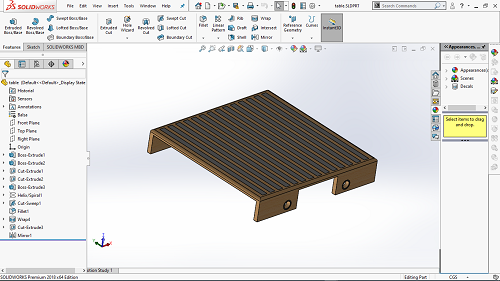

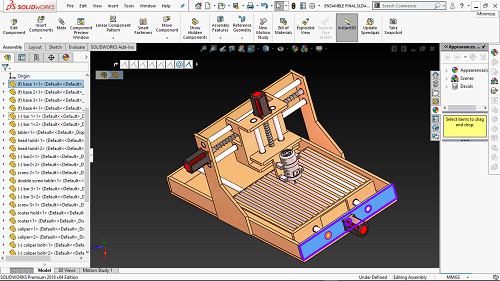

CAD designs

First we decided to make designs that will be very easy to manufacture

bearing in mind that we would love to use the material that is available with them to manufacture

Thats how the final assembly would look like at the end and the choise of material being wood

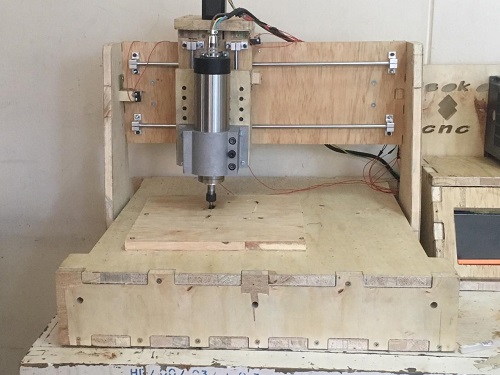

cnc cutting and assembly

Most of the wood frames was cut using cnc at the lab

as part also of cnc learning we decided to make joints for the frames and as a way of fastening we used wood screws as well as wood glue to make the whole machine be firm

We went ahead and decided to route wires for all the steppers and other electronics that we we getting ourselves involved in

for the trials and testing we decided to leave the machie open incase we burn or have a miss connection somewhere

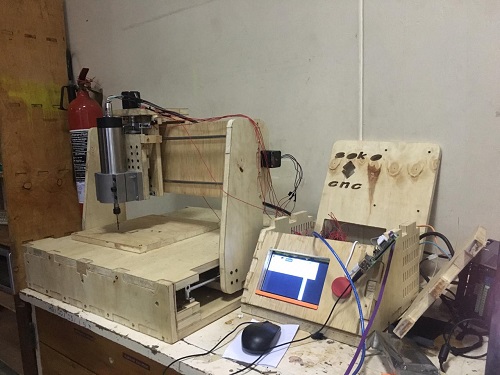

grbl and cnc prgraming

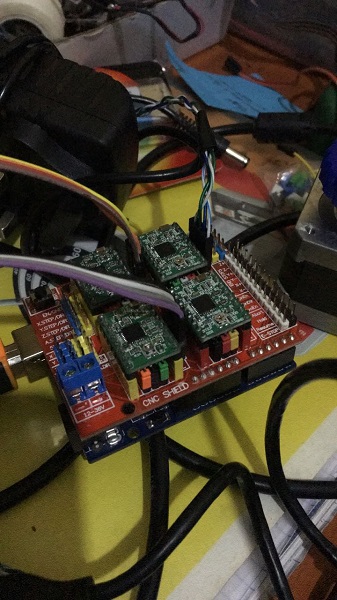

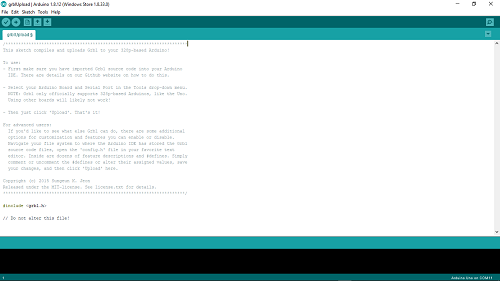

Since we did not have time to program our own software we decide to go open source and having the the following board

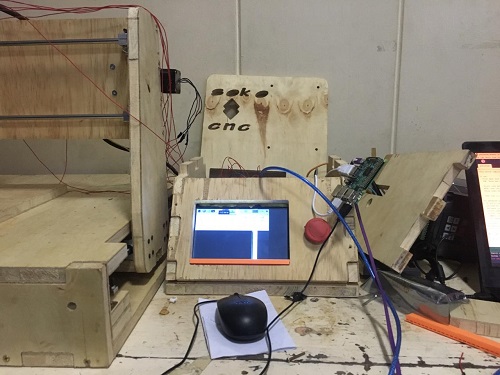

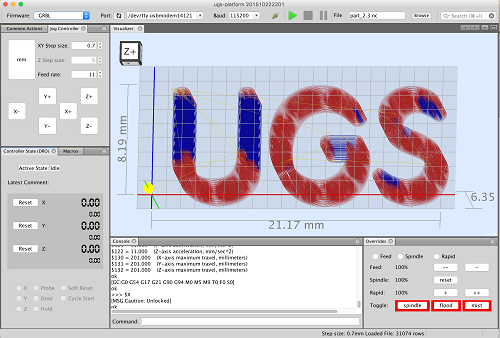

We decided to choose software which are compatible with it. we came across mant other but we decide to settle on GRBL motion control software. Here is the link to github account: https://github.com/gnea/grbl

Ater choosing the software of opertation we had to choose a way to communicate with the hardware movement and we settled for universal gcode sender software. Here is a link to getting it: https://winder.github.io/ugs_website/

testing of the machine

this is during the test of cnc and assembly

Problem faced

you can get the files

Design files